What Are Rivet Nuts?

Leading Rivet Nut Manufacturer and Supplier in China

Rivet nuts serve as essential fasteners, securing threaded connections in thin or soft materials across various industrial and engineering fields. This content will start from what are rivet nuts, and give a detailed introduction to the riveted screws.

By reading this blog, you will have a comprehensive understanding of the various types of rivet nuts and rivet nut applications, which will help you better choose the right riveted nut solution.

Table of Contents

Rivet Nut - What Are They & Why We Use Them

What are rivet nuts?

Invention History: Rivet nuts, invented in the 1930s, were originally designed for the aerospace industry to provide strong threaded connections in thin materials.

Classification: They are categorized by material (e.g., steel, stainless steel, aluminum) and design (e.g., flat head, countersunk, hex body). Each type serves specific requirements, from load-bearing applications to corrosion resistance.

What is the purpose of using rivet nut?

The purpose of using rivet nuts is to provide a secure, durable threaded connection in materials that are too thin, soft, or inaccessible to support traditional threading.

They are particularly valuable for lightweight designs, materials with limited structural integrity, and situations requiring installation from one side (blind applications).

Rivet nuts enable the creation of strong and reliable fastening points for bolts or screws, making them essential for applications in industries like automotive, aerospace, electronics, and construction.

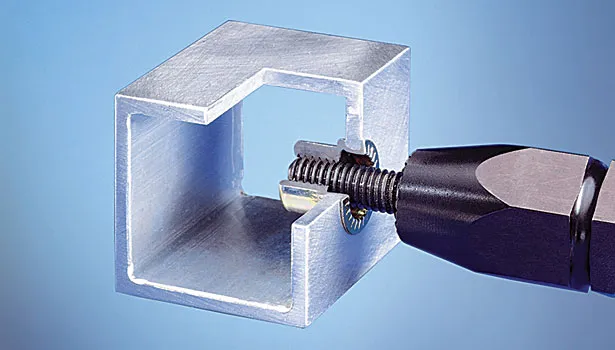

Rivet nuts are a fastener that can quickly form an internal threaded connections in thin sheets or tubular materials. Its working principle relies on plastic deformation, where a special tool deforms the rivet nut to secure it in place on the base material, forming a stable threaded connection.

Basic Structure of a Rivet Nut

- Threaded Section: The inner hole with standard threads for bolt connection.

- Cylindrical Body: The main body that fits into the material.

- Deformable Zone: Typically the lower end or a flange that deforms to lock the nut in place.

- Flange (Head): Provides additional support to prevent loosening and improve load distribution.

Working Principle

The rivet nut is installed through the application of axial force using a specialized tool, causing the deformable section to expand or flare, creating a strong mechanical bond with the workpiece.

Do You Have Any Questions?

Let Us Solve Your Problem

Pros & Cons of Rivet Nuts

Understanding the pros and cons of rivet nuts will help in deciding whether they are the best solution for a particular application.

Pros

1. Versatile Application:

Suitable for thin materials where traditional threading isn’t feasible.

Can be used on metal, plastic, composite, and other materials.

2. Blind Installation:

Blind installation refers to the process of securing a fastener from one side of the material without requiring access to the other side. This feature makes rivet nuts and similar fasteners ideal for applications where the backside of the workpiece is inaccessible (such as enclosed tubes, walls, or closed compartments).

3. No Heat Required:

Unlike welding, rivet nuts do not require high temperatures, preserving material integrity.

4. Strong and Durable:

Provides a reliable and robust threaded connection.

Handles high torque and vibration-resistant conditions well.

Cons

1. Specialized Tools:

Requires specific installation tools (manual riveters, pneumatic tools) that add to initial setup costs.

2. Load Limitations:

Rivet nuts have load limitations based on material strength, size, and installation method. In general, they are best suited for medium to light loads, with high-strength materials or thicker rivet nuts used for more demanding applications. Always check specifications for precise load ratings.

3. Material Thickness Dependency:

For thin materials, they provide a strong, reliable connection. However, effectiveness can be reduced in very thin or soft materials without adequate reinforcement.

For thick materials, the installation process may require more force, and the rivet nut’s holding power can be limited. If the material is too thick, a larger or more robust rivet nut may be necessary to ensure a secure and durable connection. Always choose the right size and type based on the material thickness for optimal performance.

4. Surface Preparation:

Requires precise hole sizing and alignment for proper installation, demanding attention to detail during preparation.

5. Risk of Over-Torquing:

Over-torquing rivet nuts can lead to various issues, including stripping the threads, damaging the material, or causing the rivet nut to fail.

When the torque exceeds the recommended limits, it can distort the nut, causing it to lose its grip on the material or result in poor thread engagement. Always follow the manufacturer’s guidelines for torque specifications to ensure the rivet nut provides a secure and reliable fastening.

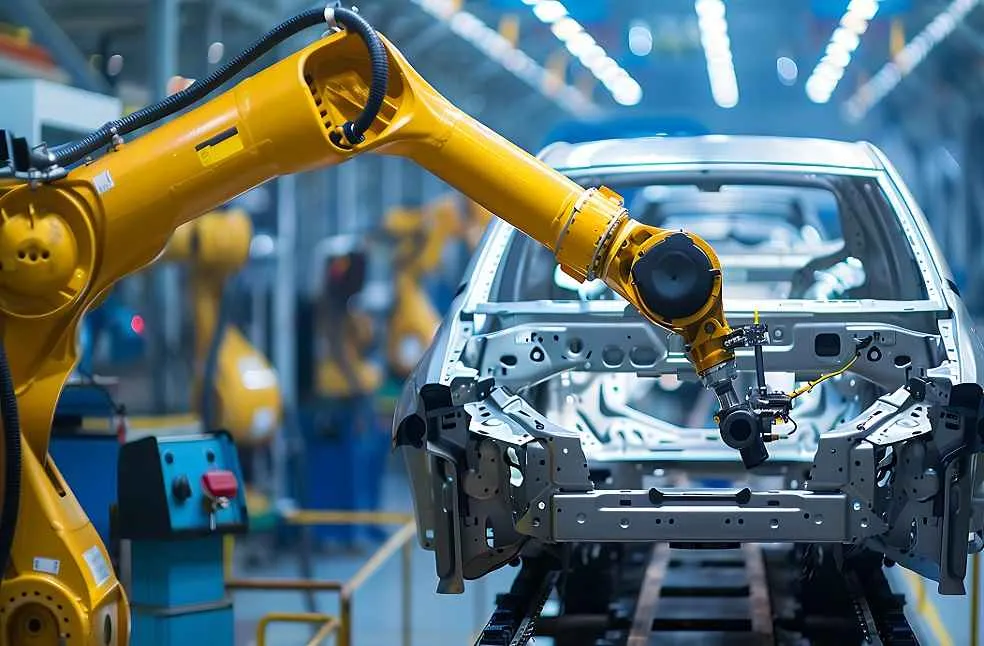

Automotive

Automotive industries are commonly use them to connect lightweight body panels, engine parts and trim to ensure that parts do not damage thin metal sheets.

Aerospace

Rivet nuts play a crucial role in aircraft structures, offering high strength and low weight for securing panels, frames, and electrical components.

Electronics

The electronics industry uses them to secure circuit boards, housings, and other electronic components to ensure stable connections.

Construction

They provide secure attachments in thin sheet metal used in building systems, including HVAC and roofing.

Marine

Their corrosion-resistant properties make them ideal for securing components in marine environments.

We can use rivet nuts as versatile fasteners in a wide range of applications across multiple industries. Their versatility allows them to create strong, reliable threaded connections in thin or soft materials.

Do You Have Any Questions?

Let Us Solve Your Problem

Drill a Hole

Use the appropriate drill bit size to create a hole in the material that matches the diameter of the rivet nut.

Insert the Rivet Nut

Place the rivet nut into the hole. It should fit snugly without excessive play.

Select the Installation Tool

Choose a manual, pneumatic, or hydraulic tool that suits the size of the rivet nut you’re using. Tools typically feature a mandrel that threads into the rivet nut.

Manual Tools: Simple hand tools, ideal for small volumes.

Pneumatic Tools: Powered by air, these tools offer faster installation, suitable for medium-volume tasks.

Hydraulic Tools: Provide high force for large or industrial applications, ideal for high-volume or heavy-duty tasks.Compress the Rivet Nut

Operate the tool to pull the mandrel, causing the rivet nut to expand and securely clamp the material.

Remove the Tool

Once the rivet nut is fully compressed, release the tool and remove it. The rivet nut should now be securely fastened. Ensure the rivet nut is properly installed and does not spin or shift.

Hex Body Rivet Nuts

Hex Body Rivet Nuts provide secure threaded connections by gripping materials with their hexagonal design. Their shape resists rotation under torque and ensures reliable fastening, even in challenging materials. Industries such as automotive, construction, and electronics frequently use them for durable and high-torque applications.

Knurled Body Rivet Nuts

Knurled Body Rivet Nuts enhance grip by using a ridged, knurled surface that increases friction between the nut and the material. This design prevents slipping or loosening under vibration or load. Applications in industries such as aerospace, electronics, and machinery rely on these rivet nuts for secure, long-lasting connections in both hard and soft materials.

Round Body Rivet Nuts

Round Body Rivet Nuts secure materials by providing a smooth, cylindrical body that fits snugly into drilled or punched holes. This design works well in applications requiring quick, easy installation without special anti-rotation features. Industries such as electronics, automotive, and furniture use these rivet nuts for lightweight and versatile fastening solutions.

Are Rivet Nut Watertight?

- Standard Blind Rivet Nuts: These blind rivets are not watertight because their design includes threads and expansion features that can allow water to pass through.

- Sealed Blind Rivet Nuts: Similar to standard rivet nuts, the mandrel on this rivet nut is completely enclosed, making it watertight. These solutions are often used in applications requiring moisture resistance, such as in automotive or marine environments.

Are Rivet Nut Permanent?

Rivet nuts are considered permanent fasteners because they are installed securely into materials by expanding and creating a tight hold. Once installed, they typically remain in place and provide a durable threaded connection.

So it can’t be moved, at least not removable without a high risk of damaging the fixed material.

Can I Use Steel Rivet Nut in Aluminum?

The answer is you can’t use steel Rivet nuts in Aaluminum.

Alumunium rivets in steel will cause corrosion to set in and destroy the rivets, leading to failure in the fastener. When steel and aluminum come into contact, especially in the presence of moisture, electrochemical reactions can occur, leading to material degradation over time. Likewise, it’s the same reason you can’t use steel rivets in alumunium.

Preventing galvanic corrosion means choosing metals close in the galvanic series to minimize the potential difference that drives corrosion. For example, pairing metals like aluminum and zinc, which are closer in the series, reduces the risk compared to pairing aluminum with steel.

To mitigate this situation:

- Use a coating or plating on the steel rivet nut, such as zinc.

- Apply an insulating barrier like a gasket or sealant.

- Choose stainless steel rivet nuts, which are less prone to corrosion in mixed-metal assemblies.

Can I Use Rivet Nut In Wood?

Yes, rivet nuts can be used on wood. However, it is worth noting that depending on the type of wood, the rivet nut may not expand effectively. Rivet nuts are suitable for hard, thin wood, such as laminated wood in furniture construction. But for soft wood such as red pine, the effect may not be ideal.

So, make sure the wood is dense enough for the rivet nut to grip and hold.

Do You Have Any Questions?

Let Us Solve Your Problem

Choose Rivetfix to Advance Your Project

Rivetfix is the first choice for the manufacturer of riveted nuts with its wide range of solutions, services and corporate vision. Whatever your field and nature of the project, we can choose the best product for your needs.

Get free sample proofing or request an instant quote to improve the efficiency of your project now.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.