Rivet Nut Dimensions - The Ultimate Guide

Leading Rivet Nut Manufacturer and Supplier in China

Rivet nut dimensions are crucial for ensuring the right fit and performance in various applications. Whether you are working with metals, plastics, or composites, understanding the key dimensions of rivet nuts helps ensure a secure, reliable connection. In this blog, we’ll dive into the essential rivet nut dimensions you need to consider for your project, helping you make informed decisions to achieve optimal results.

Table of Contents

What is the Rivet Nut Dimension?

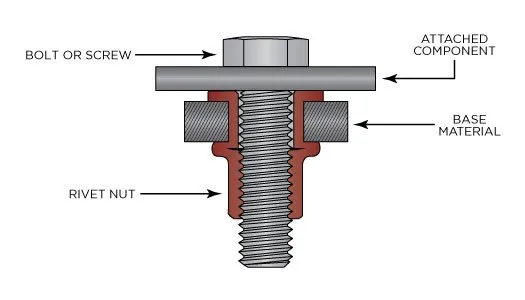

Rivet nuts are fasteners commonly used to create long-lasting threaded connections, often in soft materials such as metals, plastics, and composites. Additionally, they can be installed without back access and are widely used where fast and efficient installation is required. The rivet nut mechanically expands its housing into the hole, forming a solid threaded connection that allows the material to withstand tightening by bolts or screws like metal.

Furthermore, the installation process of the rivet nut is simple and can withstand high loads with minimal damage to the material. Common applications include automotive, aerospace, construction, and electronic devices for connecting internal and external parts. Especially in the case of thin or fragile materials, choosing the right rivet nut can greatly improve installation efficiency and connection strength.

Rivet Nut Dimensions

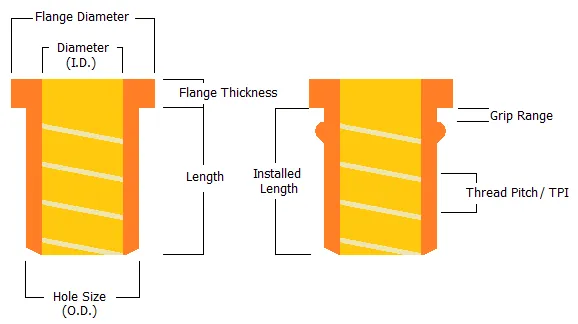

Rivet nut dimensions refer to the specific measurements that define the size, shape, and thread specifications of a rivet nut. In addition, these dimensions include the outer diameter, grip range (the thickness of the material the rivet nut can fasten), thread size, and length, which are critical for ensuring proper fit and functionality.

Moreover, choosing the correct rivet nut dimensions ensures a secure and durable connection, while also helping to meet the performance requirements of different applications. By selecting the right dimensions, you can ensure optimal installation and reliable performance for your projects.

Components of Rivet Nut Dimensions

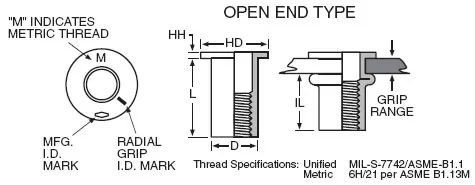

a. Thread Size (External and Internal)

The thread size of a rivet nut refers to both its external and internal threads. Proper matching of the external and internal thread sizes is crucial for achieving optimal performance, including load-bearing capacity and ease of installation.

- External Thread Size: This is the diameter of the rivet nut’s external threads, which determine the size of the hole required for installation. Common external thread sizes range from M3 to M16, though larger sizes are available for specific applications.

- Internal Thread Size: This refers to the size of the threaded hole inside the rivet nut, where bolts or screws are fastened. The internal thread size must match the bolt or screw size that will be used, such as M3, M4, M5, etc., ensuring a secure connection.

b. Length

Rivet nut length refers to the overall length of the rivet nut. Length determines how deep the rivet nut will sit in the material. It can vary depending on the application and the thickness of the material it is designed to fasten.

Common Lengths for Rivet Nuts:

- M3 to M5 Sizes: Typically range from 6 mm to 10 mm.

- M6 to M8 Sizes: Typically range from 8 mm to 12 mm.

- M10 to M12 Sizes: Typically range from 10 mm to 15 mm.

- Larger Sizes (M14, M16, etc.): These can range from 12 mm to 20 mm or more, depending on the specific application and material thickness.

c. Body Diameter

The body diameter of a rivet nut refers to the outer diameter of the cylindrical body that makes contact with the material when the rivet nut is installed. In addition, the body diameter must match the hole diameter in the material to ensure proper installation and maximize the load-bearing capacity.

Moreover, it plays a key role in determining the strength and stability of the connection, as it affects how much surface area the rivet nut will distribute the load across. Therefore, selecting the correct body diameter is essential for ensuring a secure and durable connection.

Common Body Diameters for Rivet Nuts:

- M3 Size: Typically 5 mm body diameter.

- M4 Size: Typically 6 mm body diameter.

- M5 Size: Typically 7 mm body diameter.

- M6 Size: Typically 8 mm body diameter.

- M8 Size: Typically 10 mm body diameter.

- M10 Size: Typically 12 mm body diameter.

- M12 Size: Typically 14 mm body diameter.

The grip range of a rivet nut refers to the thickness of the material that the rivet nut is designed to securely fasten. Specifically, it defines the minimum and maximum material thickness that the rivet nut can effectively clamp onto. Consequently, this range ensures that the rivet nut provides a reliable and secure connection. Furthermore, the grip range plays a crucial role in ensuring the rivet nut expands correctly and holds the threaded insert firmly in place within the material, contributing to the strength and stability of the connection.

- Minimum Thickness: The thinnest material that can be effectively fastened by the rivet nut.

- Maximum Thickness: The thickest material that can still achieve a secure connection using the rivet nut.

- M3 Size: Typically 0.5 to 2.0 mm grip range.

- M4 Size: Typically 0.5 to 2.5 mm grip range.

- M5 Size: Typically 0.8 to 3.0 mm grip range.

- M6 Size: Typically 1.0 to 4.0 mm grip range.

- M8 Size: Typically 1.5 to 5.0 mm grip range.

- M10 Size: Typically 2.0 to 6.0 mm grip range.

- M12 Size: Typically 2.5 to 7.0 mm grip range.

5. Flange Diameter

The flange diameter of a rivet nut refers to the outer diameter of the flange, which is the part that sits against the surface of the material being fastened. The flange helps to distribute the load and prevents the rivet nut from pulling through the material. It provides stability during installation and ensures the nut remains securely in place.

Key Considerations for Flange Diameter:

- Load Distribution: A larger flange diameter helps distribute forces over a wider area, providing better stability and strength.

- Material Compatibility: The flange diameter should be chosen based on the thickness and strength of the material to avoid damage or ineffective connections.

- Size Range: Flange diameters vary based on the size of the rivet nut. For example:

- M6 rivet nut: The flange diameter might range from 10 mm to 12 mm.

- M8 rivet nut: The flange diameter could be around 13 mm to 16 mm.

6. Material and Finish

While not technically part of the dimensional specifications, the material (steel, stainless steel, aluminum, etc.) and the finish (zinc-plated, anodized, etc.) will impact the performance and suitability of the rivet nut for specific environments.

Material Options:

- Steel rivet nuts: Offers high strength and load-bearing capacity, often used in automotive, aerospace, and construction applications.

- Stainless steel rivet nuts: Known for excellent corrosion resistance, making it ideal for use in marine, chemical, and food industries.

- Aluminum rivet nuts: Lightweight and corrosion-resistant, aluminum rivet nuts are used in industries where weight is a key consideration, such as aerospace.

- Copper rivet nuts: Corrosion-resistant and highly conductive, used in electrical applications.

- Plastic: Suitable for applications in which the material should not damage or corrode, like in certain electronics or light-duty applications.

Finish Options:

- Zinc Plating: Offers a basic layer of corrosion resistance for general-purpose applications.

- Anodized: Anodized aluminum provides enhanced corrosion resistance and a more durable finish.

- Chrome Plating: Provides a smooth, shiny finish with increased resistance to corrosion and wear.

- Nickel Plating: Offers superior resistance to corrosion and is often used in harsh environments.

Do You Have Any Questions?

Let Us Solve Your Problem

Thread Size (External and Internal)

External Thread:

- Measure the outer diameter of the rivet nut’s external threads using a caliper or a micrometer. This dimension is crucial for selecting the correct bolt or screw that will thread into the rivet nut.

- Standard external thread sizes for rivet nuts range from M3 to M12 (metric) or #4 to 1/2 inch (imperial).

Internal Thread:

- The internal thread diameter is the key measurement for ensuring the rivet nut accommodates the correct size bolt. Measure the inner diameter using a thread gauge or micrometer to get the exact measurement.

- Rivet nuts typically have internal thread sizes that correspond to their external threads (e.g., M6 external thread typically pairs with M6 internal thread).

Length

- The length of the rivet nut is the distance from the base (flange area) to the end of the nut body.

- How to Measure: Use a caliper to measure from the base of the flange to the end of the nut. This dimension affects how deeply the rivet nut will sit in the material, ensuring it provides adequate grip.

- Lengths of rivet nuts can vary from 5mm to 20mm or more, depending on the application requirements.

Body Diameter

- The body diameter refers to the outer diameter of the rivet nut excluding the flange.

- How to Measure: Measure across the nut body with a caliper to get the outermost dimension of the body.

- The body diameter is critical for determining the hole size that must be drilled in the material before installing the rivet nut.

- Typical body diameters for rivet nuts range from 5mm to 14mm.

Grip Range

- The grip range refers to the material thickness the rivet nut is designed to fasten. It is the range of material thickness that the rivet nut can securely grip once installed.

- How to Measure: This is typically listed as a range by the manufacturer, e.g., 0.5mm to 6mm.

- It is important to select a rivet nut with a grip range that matches the material thickness for a secure and tight fit.

- Rivet nuts are generally designed for use in materials like aluminum, plastics, thin steel, composites, and fiberglass.

Flange Diameter

- The flange diameter is the width of the flange, which provides surface area and support once the rivet nut is installed.

- How to Measure: Measure across the flat surface of the flange from edge to edge. This provides stability and prevents the rivet nut from pulling through the material.

- The flange diameter is an important factor for load distribution, with typical diameters ranging from 8mm to 20mm, depending on the rivet nut’s size and material.

Do You Have Any Questions?

Let Us Solve Your Problem

Perfect Fit: Custom dimensions ensure the rivet nut fits perfectly into your application, improving the performance and reliability of the connection. Additionally, tailored dimensions can increase efficiency, providing a seamless fit that optimizes the overall installation process.

Increased Performance: Tailored dimensions can enhance the load-bearing capacity, shear strength, and durability, providing better results in demanding applications. As a result, you can achieve greater reliability and longevity in your connections.

Cost-Efficiency: By selecting custom sizes, you reduce the risk of selecting the wrong rivet nut, minimizing waste and avoiding rework. Consequently, this leads to more cost-effective projects with fewer setbacks.

Rivetfix - Leading Jack Nut Supplier in China

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Our commitment to quality, innovation, and customer satisfaction has established Rivetfix as a trusted partner for businesses seeking reliable fasteners. We prioritize the use of premium materials, cutting-edge technology, and rigorous quality control processes to ensure that our jack nuts meet international standards and exceed customer expectations. In addition, as a global supplier, Rivetfix offers competitive pricing and fast delivery, making us the ideal choice for your jack nut needs. Consequently, you can rely on us for exceptional performance and dependable service.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.