How to Choose the Right Rivet Nuts for Fiberglass?

Leading Rivet Nut Manufacturer and Supplier in China

Choosing the right rivet nuts for fiberglass is crucial to ensuring strong, reliable connections without damaging the material. Fiberglass, known for its lightweight and durable properties, requires careful consideration when selecting fasteners. In this blog, we will explore the factors to consider when choosing rivet nuts for fiberglass.

Table of Contents

What is Fiberglass?

Fiberglass is a composite material made from extremely fine strands of glass, typically around 5 to 10 microns in diameter. These glass fibers are woven into mats, custom cloths, or roving, which are then bonded together with a resin, usually epoxy, polyester, or vinyl ester. This process creates a durable, solid composite material known for its strength, lightweight properties, and resistance to various environmental factors.

Fiberglass offers excellent mechanical strength while maintaining a low density, making it ideal for applications where both strength and weight are crucial considerations. It is highly resistant to corrosion, chemicals, and high temperatures, which makes it suitable for use in harsh environments like marine vessels, automotive parts, industrial equipment, and electrical insulation. Additionally, fiberglass can be molded into complex shapes, providing flexibility for designers and manufacturers across multiple industries.

Will Rivet Nuts Work in Fiberglass?

Yes, rivet nuts can work in fiberglass, but certain considerations are important to ensure effective installation and a strong connection. Fiberglass, being a composite material, can be prone to cracking or damage if too much force is applied during installation. Here’s how rivet nuts work in fiberglass:

1. Material Compatibility

Rivet nuts provide a secure threaded insert in fiberglass, especially when the material is thick enough to support the installation process.

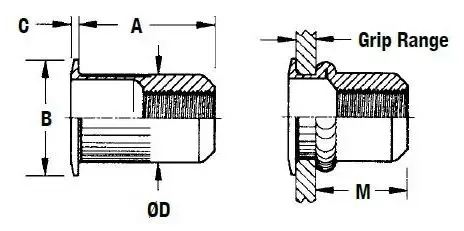

A minimum material thickness is usually required for rivet nuts to expand properly without causing damage to the fiberglass. Typically, a thickness of at least 1/8 inch (3 mm) is recommended, though this can vary depending on the size of the rivet nut.

If the fiberglass material is too thin, brittle, or improperly oriented, it may not hold the rivet nut securely, leading to potential damage or failure of the connection. In these cases, alternative methods, such as using larger diameter rivet nuts or reinforcing the fiberglass with additional layers or materials, may be necessary.

2. Installation Method

Installing rivet nuts in fiberglass requires careful attention to the installation tool and technique to avoid material damage. The primary concern is preventing excessive radial expansion, which could crack or weaken the fiberglass.

Tool Settings:

Choose a hand or pneumatic rivet nut tool that allows you to control the amount of force applied during installation. Pneumatic tools are often preferred for consistent force application, but they must be adjusted to avoid over-expansion. Hand rivet nut tools provide more control and can be effective for smaller projects.

Correct Expansion Force:

For optimal installation, the expansion force should typically range from 400-800 N, depending on the fiberglass thickness and density. Thinner fiberglass (1-3 mm) requires lower force (~400-500 N), while thicker panels (5 mm or more) can tolerate higher force (~600-800 N).

Using tools with adjustable settings, such as manual or pneumatic tools, ensures consistent, controlled force. Gradually applying force during installation while monitoring the material helps prevent over-expansion and ensures the rivet nut is securely set without compromising the fiberglass. Always test on a scrap piece to fine-tune pressure and prevent damage.

3. Load Requirements

Fiberglass has a lower tensile strength than metals like steel or aluminum, which limits the load-bearing capacity of rivet nuts installed in fiberglass. Typically, fiberglass can withstand loads of 300-800 N depending on its thickness and reinforcement.

For applications with higher stress or loads, it’s essential to select rivet nuts that match the required strength. Rivet nuts made from materials like steel or stainless steel, with higher shear and tensile strength, are ideal for securing components in fiberglass. It’s also crucial to consider the type of fiberglass used (woven, mat, or chopped strand) as its strength may vary. Always consult material-specific guidelines to prevent failure under stress.

Advantages of Rivet Nuts for Fiberglass

Rivet nuts offer several advantages when used in fiberglass applications, making them an ideal choice for creating secure, reusable threaded connections in this material. By using rivet nuts, manufacturers can maintain the structural integrity of fiberglass while enjoying the benefits of a strong, secure, and versatile fastening system.

1. Strong, Reliable Connections

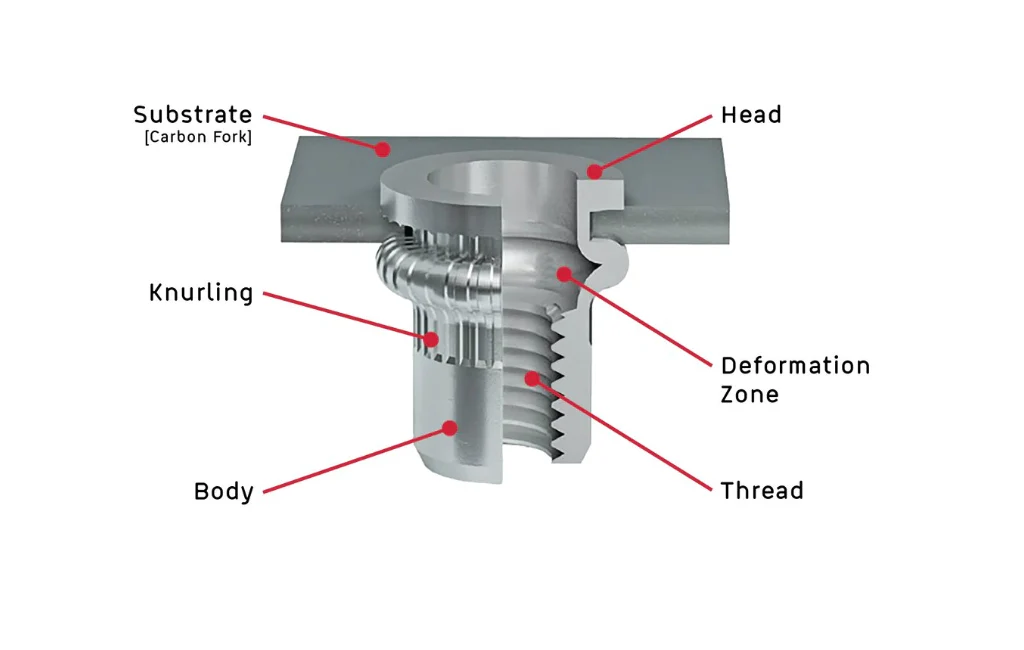

Rivet nuts create strong, reliable connections in fiberglass by forming a secure, internal thread that can hold bolts, screws, or other fasteners. When properly installed, the rivet nut expands inside the fiberglass, anchoring itself firmly in place. This ensures that the attached components remain securely fastened, even under stress or load.

The ability to provide a robust threaded connection makes rivet nuts an ideal solution in applications where high reliability and durability are needed. Unlike traditional threading methods, which can weaken the material, rivet nuts maintain the structural integrity of fiberglass while offering a dependable and long-lasting fastening point.

2. No Need for Tapping Threads

One of the main advantages of using rivet nuts in fiberglass is that they eliminate the need for tapping threads directly into the material. Fiberglass is often too brittle or difficult to tap with conventional methods, which can lead to material damage or thread failure. Rivet nuts, however, create a strong, internal threaded connection without requiring any additional threading process.

By simply installing a rivet nut, you can achieve a secure, reliable fastening point without compromising the integrity of the fiberglass. This makes rivet nuts a highly efficient solution for applications where traditional threading is not feasible or desirable, saving both time and effort during installation.

3. Reduced Weight

Rivet nuts contribute to a reduction in overall weight, which is particularly beneficial when working with fiberglass. Rivet nuts are available in materials such as aluminum, which are lighter while still providing strong and secure connections.

By using rivet nuts, you can maintain the structural integrity of the fiberglass while keeping the overall weight of the assembly low. This is especially advantageous in industries like automotive, aerospace, and marine, where weight reduction is a critical factor for performance and efficiency.

4. Improved Aesthetics

Rivet nuts can improve the aesthetics of fiberglass assemblies by providing a clean, flush finish. Since they are installed from one side and expand to create a secure grip, there is no need for exposed bolts or screws, reducing the visual clutter often associated with traditional fastening methods.

Their smooth, low-profile design allows them to blend seamlessly with the fiberglass surface, giving a polished and professional look. This feature is especially valuable in applications like automotive interiors, consumer electronics, and high-end furniture, where visual appeal is crucial.

Do You Have Any Questions?

Let Us Solve Your Problem

Best Rivet Nuts for Fiberglass

When selecting rivet nuts for fiberglass, it’s essential to choose materials and designs that optimize the performance of the rivet nuts while taking into account the unique characteristics of fiberglass.

- Advantages: Aluminum rivet nuts are lightweight, corrosion-resistant, and have a lower cost compared to steel and stainless steel. Their lightweight nature makes them ideal for applications where reducing weight is crucial, such as in automotive, aerospace, or consumer products.

- Best for: Aluminum rivet nuts are well-suited for fiberglass applications where weight reduction is a priority. They provide adequate rivet nut strength for medium-duty applications without adding unnecessary mass. For example, aluminum rivet nuts are commonly used in automotive body panels, furniture, and other lightweight fiberglass constructions.

- Advantages: Stainless steel rivet nuts offer high rivet nut strength and excellent corrosion resistance. They can withstand harsh environments, including exposure to moisture, chemicals, and high temperatures, making them highly durable.

- Best for: Stainless steel rivet nuts are ideal for high-stress, high-load applications where long-term durability and resistance to corrosion are important. For fiberglass applications exposed to the elements or industrial settings, such as outdoor enclosures, marine applications, and heavy-duty machinery, stainless steel rivet nuts are a reliable choice.

- Advantages: Copper rivet nuts are known for their good electrical conductivity and resistance to corrosion. They are often used in electrical applications because they provide an excellent conductive path.

- Best for: Copper rivet nuts are best suited for fiberglass applications where electrical conductivity is important. In electronics or electrical enclosures made from fiberglass, copper rivet nuts ensure secure mounting while offering superior conductivity, ideal for grounding or electrical connections in sensitive applications.

- Advantages: Knurled or serrated rivet nuts have textured outer surfaces, which help to prevent rotation within the material. These added features enhance grip and provide better torque resistance, particularly in soft or brittle materials like fiberglass.

- Best for: These types of rivet nuts are ideal for use in fiberglass when you need to prevent the rivet nut from rotating or loosening under stress. They work well in applications where the fiberglass is thinner or where load-bearing capacity is moderate, such as in consumer electronics or automotive interiors, ensuring a strong and secure hold.

- Advantages: Reduced head rivet nuts are designed with a smaller flange, offering a more compact and low-profile installation. Their reduced head height minimizes the intrusion into the material surface, providing a cleaner, more aesthetic finish.

- Best for: When aesthetics are a priority, such as in visible fiberglass parts for automotive interiors, furniture, or electronics, reduced-head rivet nuts provide a smooth, flush appearance. These are also excellent when working in confined spaces where traditional rivet nuts may not fit or would be too bulky.

How to Choose Rivet Nuts for Fiberglass?

Choose the Right Material:

Fiberglass is a lightweight, durable material, but it has limited tensile strength. Select rivet nuts made of materials like aluminum or stainless steel depending on your application’s load and environmental conditions. Aluminum is ideal for lightweight applications, while stainless steel is better for heavier-duty applications or those exposed to moisture, chemicals, or extreme conditions.

Assess Load Requirements:

Fiberglass has lower tensile strength compared to metals. Therefore, a rivet nut with the right rivet nut tensile strength is selected to ensure that it can withstand the expected load without damaging the material. Aluminum rivet nuts are suitable for medium-duty loads, while stainless steel rivet nuts should be used for heavier loads and high-stress environments.

Use Proper Tools:

The installation of rivet nuts in fiberglass requires precise control of the expansion force to avoid cracking. Using tools that provide controlled radial expansion, such as hand or pneumatic rivet nut tools, is essential. Ensure that the tool applies even pressure to create a secure grip.

Select the Right Thread:

Fiberglass is often used in applications that require secure connections for bolts, screws, or other fasteners. Choose a thread pitch (distance between threads) and type (e.g., metric or UNC) that match the bolts or screws you plan to use.

Choose the Right Head Style:

Rivet nuts come with different head designs such as flat, countersunk, and reduced head. For a low-profile, clean finish, consider using reduced-head rivet nuts, especially if aesthetics are important in your application. For applications that require a strong grip, knurled or serrated rivet nuts provide additional security and prevent rotation.

Can You Use Jack Nuts in Fiberglass?

Yes, jack nuts can be used in fiberglass. In fact, jack nuts is the most suitable type for fiberglass materials. Unlike rivet nuts, jack nuts are more suitable for soft materials.

For optimal performance, the fiberglass should be at least 1.5 mm to 2 mm thick, as this allows the jack nut to expand properly and form a secure thread. The jack nut expands inside the material, creating a threaded insert without the need for tapping, making it ideal for applications where direct threading is not possible. It’s essential to use controlled expansion force (typically between 4,000 to 6,000 N for jack nuts) to avoid cracking the fiberglass.

When selecting jack nuts for fiberglass, consider the material’s load-bearing capacity. Fiberglass typically has a tensile strength of around 50-120 MPa, which is lower than metals. Therefore, choose jack nuts with appropriate load ratings based on the specific application. For example, choose jack nuts rated for at least 1,000 N tensile strength for standard applications.

Do You Have Any Questions?

Let Us Solve Your Problem

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Our factory manufactures 400 million pieces of structural rivets and automobile blind rivets, 1 billion standard blind rivets annually now. We can select the most suitable fasteners according to your project needs, and provide product customization services. Choose Rivetfix for your next project and experience the difference that superior rivet nut solutions can make.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.