Buy Self-Clinching Studs

Self-Clinching Studs create permanent threads in thin sheet metal without additional hardware. Installed by applying pressure, they clinch into place, forming a strong connection. Available in stainless steel, carbon steel, and aluminum, they accommodate various thread sizes for versatile use.

Perfect for industries like electronics, automotive, and aerospace, self-clinching studs provide a space-saving solution for thin panels. They eliminate the need for nuts, welding, or extra fasteners. This simplifies assembly, enhancing efficiency and reliability in manufacturing processes.

Home » Self-Clinching Studs

Key Features of Self-Clinching Studs

- Permanent Fastening Solution: Provides a secure, permanent threaded connection in thin sheet metal.

- Easy Installation: Easily installed with pressure, requiring no additional hardware or welding.

- High Strength: Offers a durable and robust connection capable of withstanding high loads.

- Variety of Thread Sizes & Materials: Available in multiple thread sizes and materials, including carbon steel, stainless steel, and aluminum.

- Compact Design: Saves space, making them ideal for compact and efficient designs.

- Corrosion Resistance: Available in materials like stainless steel or other corrosion-resistant options for harsh environments.

Why You Should Choose Self-Clinching Studs

- No Additional Hardware Needed: Eliminate the need for nuts, washers, or welding, saving assembly time and cost.

- Improved Efficiency: Fast and reliable installation in mass production environments.

- Reduced Material Damage: Designed to minimize the risk of panel deformation during installation.

- Strong, Permanent Fastening: Provides a durable and long-lasting fastening solution.

Versatile Applications of Self-Clinching Studs

Electronics and Electrical Equipment

In electrical equipment, self-clinching studs can be used to provide grounding points for cables and other conductive parts.

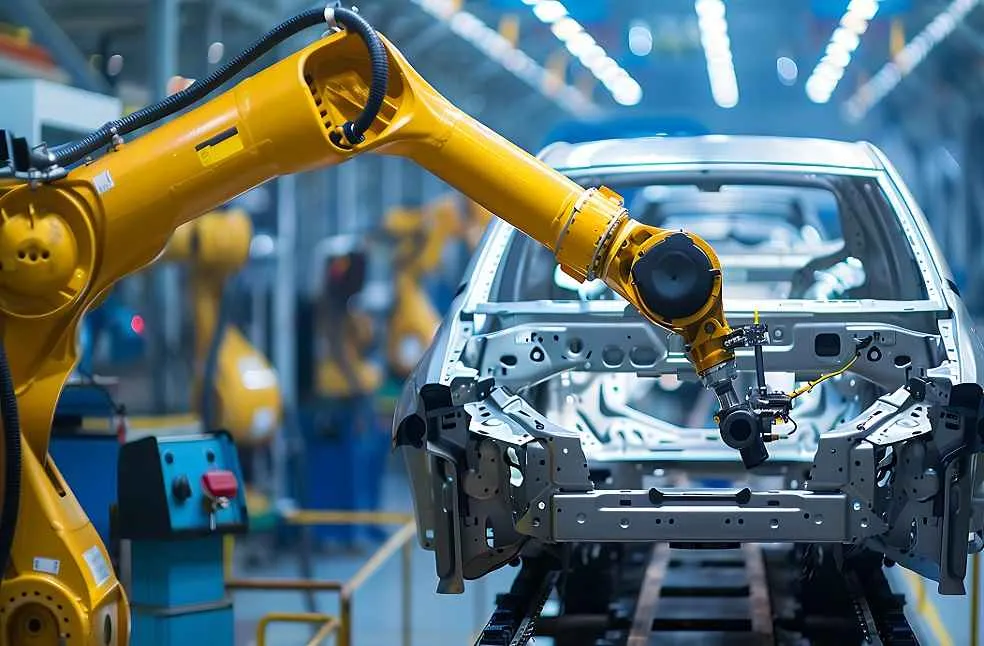

Automotive Industry

In car interiors, such as dashboard components or seating, self-clinching studs allow for the attachment of components securely to thin metal panels.

Industrial Equipment

Used in heavy machinery to fasten parts where accessibility is limited and the fastening system must withstand vibrations and heavy loads.

Consumer Electronics

The electronics industry uses self-clinching studs to secure metal housings, brackets, and other internal components in small, tightly assembled devices like laptops, smartphones, and tablets.

Renewable Energy (Solar and Wind)

Self-clinching studs are often used in the assembly of solar panels, where they secure the panels to the mounting frames or brackets. And they are used in the construction of wind turbines for attaching parts and ensuring the integrity of structural assemblies.

Custom Self-Clinching Studs For Your Project

No matter what scenario you want to use the self-clinching studs in, please consult us for professional advice and technical support.

How to Install Self-Clinching Studs

By following these steps carefully, you can ensure a secure, long-lasting attachment for the self-clinching stud. So it can meeting both safety and performance standards.

Installation Steps

1. Prepare the Hole:

Begin by cutting a hole in the workpiece that is slightly larger than the outer diameter of the fixing thread of the self-clinching stud. The hole should be sized to allow the stud to fit easily without excessive play but also provide enough room for proper clinching during installation.

2. Insert the Self-Clinching Stud:

Place the self-clinching stud into the prepared hole. Ensure that the stud is aligned correctly with the hole and that the stud’s body is positioned properly to allow for secure embedding into the material.

3. Adjust Riveting Machine Settings:

Before proceeding, carefully adjust the pressure settings on the riveting machine to the recommended values for the specific size and material of the stud and workpiece. Proper pressure is essential for ensuring that the stud clinches securely without damaging the workpiece or the fastener.

4. Apply Pressure Evenly:

Using the riveting machine, apply consistent and even pressure to the head of the self-clinching stud. The machine should slowly press the stud into the material, causing the clinching feature to embed into the workpiece. Ensure that the pressure is distributed evenly to avoid damaging the stud or the surrounding material.

Point of Attention:

1. Professional Installation Equipment Required:

The installation of both self-clinching studs and rivets must be performed using specialized, professional-grade installation machines. These machines are designed to provide the precise pressure and control necessary for a proper and secure fastening.

2. Strict Tolerance for Opening Dimensions:

The holes or openings where the self-clinching studs or rivets will be installed must be processed with a very tight tolerance, typically between 0 to 0.08 mm. This level of precision is crucial to ensure a proper fit and to avoid issues with the integrity of the fastener. In most cases, punching technology is employed to achieve the required precision.

3. Correct Pressure for Rivet Installation:

When installing rivets, it’s essential to apply the appropriate amount of pressure during the riveting process. If the pressure is too low, the rivet may not secure firmly, potentially leading to failure or a weak connection. Conversely, applying excessive pressure can cause damage to the fastener or the surrounding material. Ensuring the correct pressure ensures both the effectiveness and longevity of the riveted joint.

FAQs

1. What materials are self-clinching studs made from?

Self-clinching studs are typically made from materials such as stainless steel, carbon steel, aluminum. The choice of material depends on the application and environmental factors, such as corrosion resistance and strength requirements.

2. Do self-clinching studs require special tools for installation?

Yes, self-clinching studs must be installed using a professional installation machine that can apply the correct amount of pressure. This machine ensures proper clinching without damaging the stud or the material.

3. What types of materials can self-clinching studs be used with?

They are most commonly used with thin sheet metals, such as aluminum, stainless steel, and mild steel. They are also suitable for some plastics and composites. The material’s thickness and hardness should be considered to ensure proper installation and secure fastening.

4. What are the potential issues if installation is done incorrectly?

- Improper Hole Size: If the hole is too large or too small, the stud may not clinch properly, leading to weak attachment or failure.

- Incorrect Pressure: Too little pressure can result in an insecure stud, while too much pressure may damage the material or fastener.

- Misalignment: The stud should be installed straight and aligned to ensure even clinching and optimal strength.

5. Can self-clinching studs be removed once installed?

No, self-clinching studs are designed for permanent installation. Once clinched, they are not easily removable without damaging the surrounding material. If removal is necessary, it would typically involve cutting or drilling out the stud.

6. What is the maximum material thickness that can be used with self-clinching studs?

The maximum material thickness depends on the size of the stud and the type of material being used. Generally, self-clinching studs are most effective for sheet metal thicknesses ranging from 0.5 mm to 6 mm. For thicker materials, alternative fastening solutions may be necessary.

7. How do I choose the right self-clinching stud for my application?

When selecting a self-clinching stud, consider:

- Material compatibility: Choose a stud material that matches the workpiece material.

- Thread size: Ensure the stud has the appropriate thread size for your application.

- Hole size and tolerance: Verify the hole diameter is appropriate and meets the stud’s specifications.

- Load requirements: Match the stud’s clinching strength and size to the load it needs to support.

Have more questions?

Contact us for technical support, advice and quotes.

Buy Self-Clinching Studs in Bulk from Rivetfix

- Quality Assured: We pride ourselves on offering only the highest quality blind rivets that are both durable and inexpensive.

- Competitive Pricing: Competitive pricing is available for bulk orders, making us the first choice for buying blind rivets in bulk.

- Global Coverage: As a wholesale supplier of Blind Rivets, our products are available all over the world.

- Customer Satisfaction: Our dedicated team of professionals is committed to ensuring that you are completely satisfied with every order.

- Sustainbility: We prioritise sustainability in our manufacturing process and provide environmentally friendly packaging solutions.

Product Variants:

- Customizable Options: Offer a range of sizes, thread types, and material finishes.

- Special Designs: Include variants like flush-head, extended-stud, or low-profile designs depending on the application.

Compliance & Certifications:

Rivetfix is an ISO 9001:2015 certified self clinching stud manufacturer in the industry.

In the automotive industry, Rivetfix is a supplier of fasteners that meet the quality standards of the automotive industry.Rivetfix is quality certified to IATF 16949:2016.

Pricing & Ordering Information:

- Pricing Information: Discounted pricing is available for bulk orders.

- Minimum Order Quantities (MOQ): 50,000 units.

- Lead Time & Shipping Information: Delivery within one month. Various shipping options available.

Rivetfix, as part of Rivmate, can also supply high quality rivets and riveted parts. If you have a requirement, please contact us!