Buy Self Clinching Nuts

Self-Clinching Nut are fasteners used in sheet metal that can be pressed into the substrate during installation to create a solid threaded connection. It does not require additional nuts and bolts and can provide a reliable fixed point.

During installation, the self-locking nut forms a “locking” structure through a specially designed shape and edge during the press riveting process, so that the nut is tightly embedded in the sheet metal to achieve the effect of permanent fixation. This process ensures that the connection points remain stable in high vibration and load environments without loosening or shifting.

Home » Self Clinching Nuts

Using Self-Clinching Nuts for Strong Connections

- Strong threaded connection: The nut is pressed into the sheet metal to create a strong threaded connection without the need for additional nuts or bolts.

- No additional tools required: Easy to install, only a riveting press is required to complete the installation, and no additional screwdrivers or other fastening tools are required.

- Flush mounting: Space is saved because no external fasteners are required, making it ideal for compact design requirements. And it can be mounted almost flush on the substrate.

- High strength and durability: Good tensile strength and vibration resistance ensure that the connection points remain stable in a variety of applications.

Customizing Your Self-Clinching Nuts

Provide customized services to meet customers’ individual needs for materials, sizes, finishes and packaging.

- Self-clinching nut options are available in different models and sizes (e.g., bore, outside diameter, thread size, etc.).

- Different surface treatment options (e.g., galvanizing, passivation, anodizing, etc.) are available to improve corrosion resistance and aesthetics.

Versatile Applications of Self-Clinching Nuts

Chassis and cabinet

Used for server cabinets and electronic device shells to provide stable threaded connections for various devices.

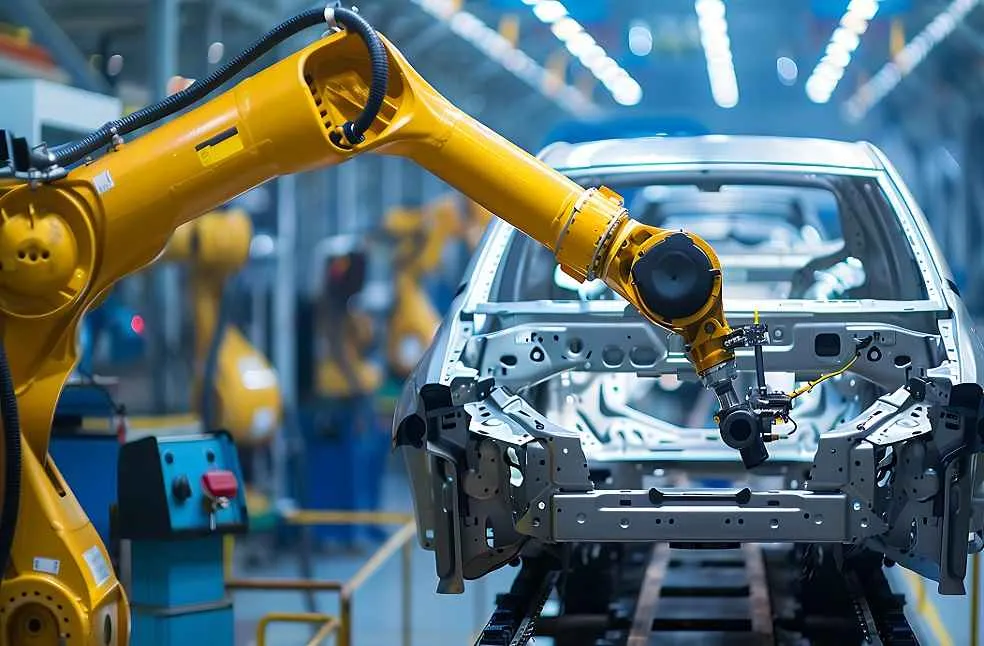

Automotive manufacturing

Provides strong connections in automotive parts, body structures, engine components, etc., especially for thin sheet metal.

Electronic products

Used for threaded connection of computer shell, communication equipment, TV, home appliances, etc., to ensure that the components are fixed.

Aerospace

High strength, shock-resistant fasteners used in aircraft, satellites and other equipment.

Industrial equipment

Widely used in the connection of various industrial machinery and equipment, especially where space is limited.

Custom self-clinching nuts for your project

No matter what scenario you want to use the self-clinching nut in, please consult us for professional advice and technical support.

How to Install Self-Clinching Nuts

Here are the installation steps and precautions for self-clinching nuts to help you achieve optimal results when pressing them into place.

Installation Steps

- Place the self-clinching nut into a lower die fixture that precisely fits the nut. The depth of the fixture hole should be equal to the outer height of the nut.

- Align the hole in the thin sheet with the self-clinching nut and place it on top.

- Press the nut into the sheet using a press.

Note: During installation, pressure should be applied to the sheet metal, not the nut.

Convex Die Fixture

The above-mentioned concave die fixture is not the only option; there is also a convex die fixture.

If the sheet metal is large or multiple nuts need to be installed on one sheet, a concave fixture may present some challenges, such as difficulty in positioning, aligning holes, and the risk of scratching the sheet. In such cases, a convex die fixture, also known as a pin-type fixture, can be used instead.

Pressing Direction

From which side of the sheet should the self-clinching nut be pressed?

Without a doubt, it should be inserted from the back side of the sheet (also called the fracture side).

The front side of the sheet (the punching side) may have slight downward indentations around the hole. During the installation of the self-clinching nut, these indentations can cause “material displacement,” leading to incomplete filling and affecting the strength of the connection.

Self-Clinching Nuts VS Rivet Nuts

Similarities:

Both fasteners serve the primary function of providing a threaded connection point in thin sheets or soft materials, facilitating subsequent screw fixation. They are both internally threaded fasteners, but their installation methods and applications differ.

Self-Clinching Nuts

- Installation Method: Installed by pressing the nut into the sheet metal using a press, creating a secure threaded connection. Once installed, the surface remains flush without any protrusions.

- Suitable Materials: Typically used in semi-finished thin sheet materials, requiring pre-drilled holes before installation.

- Installation Requirements: Requires a press for installation, demanding high precision.

- Applications: Widely used in enclosures, cabinets, equipment manufacturing, and automotive industries, especially for thin sheet metal fastening.

- Advantages:

- Provides a flush surface after installation, ideal for compact designs.

- No special tools are required, and automation systems can be used for installation.

Rivet Nuts

- Installation Method: Installed using a rivet gun, which pulls one end of the nut and compresses it into the material, forming a strong connection. Ideal for applications where access is only possible from one side or where pressing is difficult.

- Suitable Materials: Can be used in both finished and semi-finished materials, allowing installation from either side.

- Installation Requirements: Requires a specialized rivet gun.

- Applications: Suitable for areas where pressing is difficult, such as square tubes, round tubes, and other hollow structures. Rivet nuts also compensate for the limitations of welding.

- Advantages:

- Suitable for thicker base materials and maintains a nearly flush installation.

- Provides stronger threads, especially with hexagonal rivet nuts, which offer better resistance to spin-out.

- Available in various shapes and sizes, including floating thread options, offering greater flexibility.

Summary

- Self-clinching nuts are ideal for thin sheet metal applications, providing a flush surface after installation. They are primarily used in semi-finished materials and require a press for installation.

- Rivet nuts are better suited for thicker base materials and can be used in both finished and semi-finished products. They require a rivet gun for installation and are ideal for hollow materials or applications where pressing is not feasible. Rivet nuts also offer stronger threads and greater installation flexibility.

Have more questions?

Contact us for technical support, advice and quotes.

Buy Self-Clinching Nuts in Bulk from Rivetfix

- Quality Assured: We pride ourselves on offering only the highest quality blind rivets that are both durable and inexpensive.

- Competitive Pricing: Competitive pricing is available for bulk orders, making us the first choice for buying blind rivets in bulk.

- Global Coverage: As a wholesale supplier of Blind Rivets, our products are available all over the world.

- Customer Satisfaction: Our dedicated team of professionals is committed to ensuring that you are completely satisfied with every order.

- Sustainbility: We prioritise sustainability in our manufacturing process and provide environmentally friendly packaging solutions.

Quality Assurance

At Rivetfix, we are committed to providing high-quality self-locking fasteners. To ensure that every product meets the strictest standards, we implement a comprehensive quality control process. From raw material selection to final product inspection, every step is meticulously monitored to ensure precision and consistency. We utilize advanced testing equipment and precise manufacturing techniques to guarantee product performance, durability, and stability.

Furthermore, Rivetfix has obtained multiple international quality certifications, including IATF 16949:2016 and ISO certification. Our quality assurance system ensures that all products comply with international standards, meeting customers’ high demands and industry regulations.

With these measures in place, we guarantee reliable, durable, and high-performance self-locking fasteners for our customers.

Packaging & Delivery

At Rivetfix, we offer a variety of packaging options to meet different customer needs:

- Bulk Packaging: Suitable for large orders, products are packed in bulk for efficient storage and transportation.

- Custom Packaging: We provide customized packaging services according to customer requirements, including personalized packaging design, labeling, and box dimensions, ensuring product safety and brand consistency.

Delivery Time: Depending on order quantity and production schedule, the standard delivery time is within one month. We also offer expedited delivery services for urgent customer needs.

With flexible packaging and shipping options, Rivetfix ensures timely delivery of high-quality products to meet various logistical demands.

Rivetfix, as part of Rivmate, can also supply high quality rivets and riveted parts. If you have a requirement, please contact us!